Course Description:

Unlock Your Potential with Six Sigma Black Belt Training!

Are you ready to take your career to new heights and become an invaluable asset to any organization? Look no further! Our Six Sigma Black Belt training program is your ticket to success. With this comprehensive and dynamic course, you’ll gain the skills and knowledge needed to drive significant improvements, eliminate defects, and achieve near-perfect quality in any business process.

What sets Six Sigma apart and yields such impressive results? It’s all about the DMAIC framework – Define, Measure, Analyze, Improve, and Control. This proven methodology empowers you to make data-driven decisions, implement process improvements, and create lasting change that will propel your organization forward.

In the Define phase, you’ll learn how to identify and tackle the frequent challenges that hinder business processes. By closely examining every aspect, major and minor, you’ll strengthen your organization’s delivery infrastructure and lay the foundation for success.

Moving on to the Measure phase, you’ll master the art of evaluating risks and prioritizing areas that need immediate attention. Just like a savvy business owner, you’ll focus on the critical issues that can make or break your company’s performance, paving the way for smoother operations and exceptional outcomes.

The Analyze phase is where you’ll shine as a true problem-solver. By exploring potential solutions and rigorously testing each one, you’ll identify the most effective strategies to achieve your goals. Your ability to select alternatives with high potential and cost-efficiency will set you apart as a Black Belt leader.

With the Improve phase, you’ll demonstrate your expertise in project management. You’ll learn how to optimize resources, streamline processes, and expedite goal achievement within set timeframes and budgets. Your proficiency in executing tasks with precision will elevate you to the next level of success.

Finally, the Control phase ensures that your improvements are sustainable. Like a vigilant entrepreneur, you’ll monitor progress, assess results, and take corrective measures when needed. You’ll guarantee that your initiatives align with predetermined goals, driving continuous improvement and success.

Enroll in our Six Sigma Black Belt Training program and open the doors to endless opportunities. With 22 hours of comprehensive training and 50 engaging course videos, you’ll become a Certified Six Sigma Black Belt professional. Showcase your expertise in Six Sigma philosophies, principles, and supporting systems. Master the DMAIC model and apply it to drive transformative change. Gain a deep understanding of statistical and analytical methods, as well as the latest software and tools.

But that’s not all! Our course goes beyond the training. We provide you with the extra edge by preparing you for the Certified Six Sigma Black Belt exam. With our expert guidance and practice materials, you’ll approach the exam with confidence and emerge as a certified Six Sigma Black Belt, ready to make an immediate impact in any organization.

Don’t settle for mediocrity. Step into the world of Six Sigma and become a catalyst for change. Enroll now and unlock your full potential as a Six Sigma Black Belt!

What are the belts of Six Sigma?

Six Sigma White Belt – Earning a White belt certification is an indication of having the essential fundamentals of Six Sigma firmly ingrained.

Six Sigma Yellow Belt – Achieving Yellow Belt certification ensures that you have gained a thorough comprehension of the fundamentals of Six Sigma, including its applications in the workplace and where to prioritize your time as you continue to learn. As a beginner, it’s important to become acquainted with Lean Six Sigma methodology and basic tools for process improvement.

Six Sigma Green Belt – Green Belt certification concentrates on the intricate analysis and resolution of quality improvement issues. Those with a Green Belt designation will not only lead projects but also give assistance to those who have obtained Six Sigma Black Belts. If attaining your Green Belt is for you, check out our Green Belt Six Sigma online program.

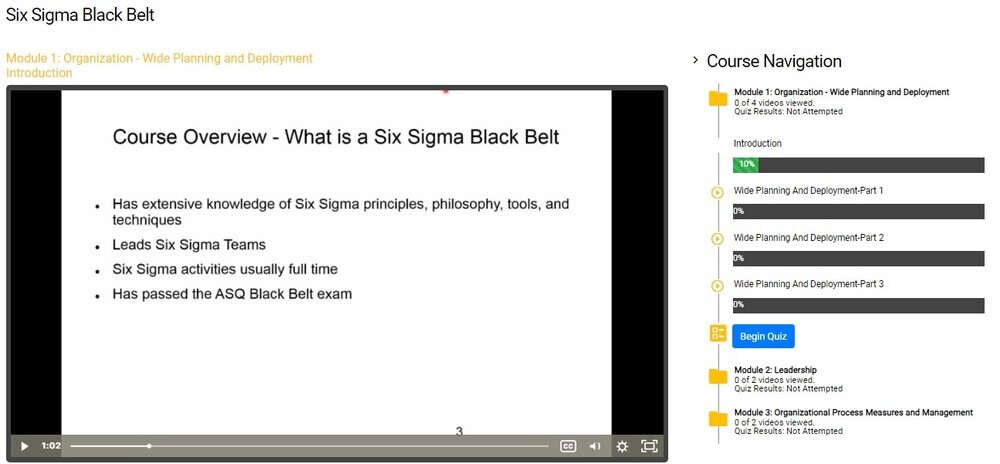

Six Sigma Black Belt – As a Six Sigma Black Belt, after taking our Six Sigma Black Belt training, you will have the advanced level knowledge and expertise to lead projects and take on the leadership role of managing teams using advanced Six Sigma tools. Certified as an agent of change in your organization, you will be responsible for driving successful project completion by utilizing all that is afforded through the methodologies associated with this philosophy.

Course Outline:

Module 1: Organization – Wide Planning and Deployment

Introduction

Wide Planning And Deployment-Part 1

Wide Planning And Deployment-Part 2

Wide Planning And Deployment-Part 3

Module 2: Leadership

Leadership-Part 1

Leadership-Part 2

Module 3: Organizational Process Measures and Management

Organizational Process Measures And Management-Part 1

Organizational Process Measures And Management-Part 2

Module 4: Team Management

Team Management-Part 1

Team Management-Part 2

Team Management-Part 3

Team Management-Part 4

Module 5: Define Phase – Overview of the Define Phase and the Voice of the

Customer

Overview Of The Define Phase And The Voice Of The Customer-Part 1

Overview Of The Define Phase And The Voice Of The Customer-Part 2

Overview Of The Define Phase And The Voice Of The Customer-Part 3

Module 6: Define Phase – Business Case and Project Charter

Business Case And Project Charter-Part 1

Business Case And Project Charter-Part 2

Module 7: Define Phase – Analytical Tools

Analytical Tools

Module 8: Measure Phase – Process Analysis and Documentation

Process Analysis And Documentation-Part 1

Process Analysis And Documentation-Part 2

Process Analysis And Documentation-Part 3

Module 9: Measure Phase – Data Collection

Data Collection

Module 10: Measure Phase – ÂMeasurement Systems

Measurement Systems-Part 1

Measurement Systems-Part 2

Module 11: Measure Phase – Basic Statistics

Basic Statistics-Part 1

Basic Statistics-Part 2

Module 12: Measure Phase – Probability

Probability

Module 13: Measure Phase – Process Capability

Process Capability

Module 14: Analyze Phase – Measuring and Modeling Relationships

Measuring And Modeling Relationships

Module 15: Analyze Phase – Hypothesis Testing

Hypothesis Testing

Module 16: Analyze Phase – FEMA and Additional Analysis Methods

FMEA And Additional Analysis Methods-Part 1

FMEA And Additional Analysis Methods-Part 2

FMEA And Additional Analysis Methods-Part 3

FMEA And Additional Analysis Methods-Part 4

Module 17: Improve Phase – Design of Experiments (DOE)

Design Of Experiments-Part 1

Design Of Experiments-Part 2

Module 18: Improve Phase – Lean Method

Lean Method-Part 1

Lean Method-Part 2

Lean Method-Part 3

Module 19: Improve Phase -Â Implementation

Implementation

Module 20: Control Phase – Statistical Process Control (SPC)

Statistical Process Control

Module 21: Control Phase – Other Controls

Other Controls

Module 22: Control Phase – Maintain Controls and Sustain Improvements

Maintain Controls And Sustain Improvements

Module 23: DFSS

DFSS

Module 24: Exam Review – Prep and Key Concepts

Prep And Key Concepts-Part 1

Prep And Key Concepts-Part 2

Prep And Key Concepts-Part 3

Prep And Key Concepts-Part 4

Prep And Key Concepts-Part 5

Lesley R. (verified owner) –

I am a big fan of Dooey Six Sigma Black Belt training course. I think it is very useful for people who want to get Lean and Six Sigma certified or for those who already have certification but wish to improve their knowledge about the subject. The course helps you understand what is necessary in order to become a Lean Six Sigma Black Belt, how can you become one, and how much time it will take until you achieve your goal. This guide gives me enough information that I know where my weaknesses are, which tools I need in order to solve them and what steps should be taken next.